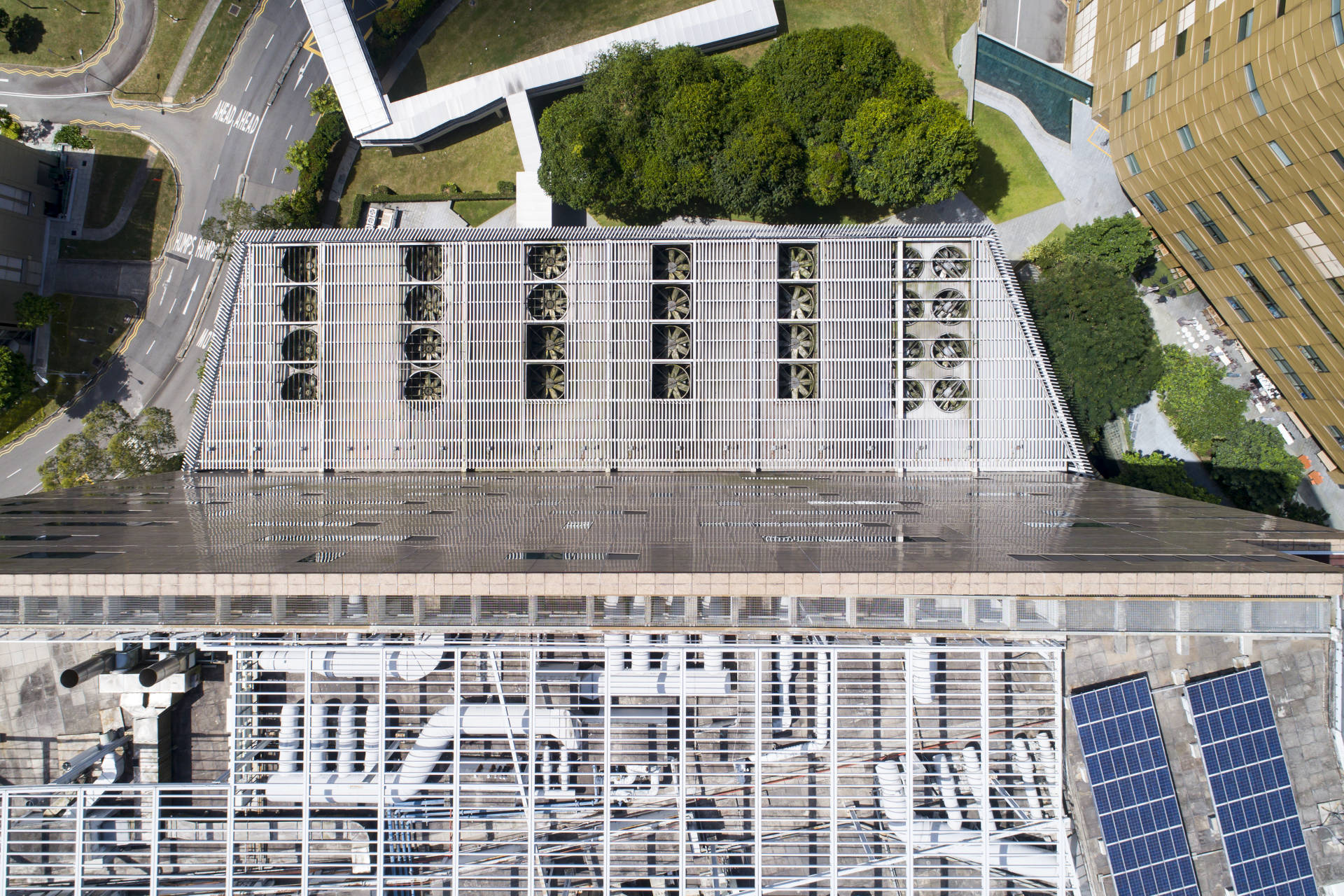

Keppel is the first and largest developer and service provider of District Cooling System (DCS) in Singapore. We develop and operate DCS at major business and industrial parks in Singapore, including Changi Business Park, one-north and Woodlands Wafer Fab Park, and the upcoming DCS in Jurong Innovation District and Jurong Lake District.

Outside of Singapore, Keppel also provides District Heating and Cooling System (DHCS) services for the Eco-Business Park located in Sino-Singapore Tianjin Eco-City, China. The plant incorporates geothermal technology to support its heating and cooling requirements. Keppel will also be providing DCS services in Sam Yan, Bangkok.

With the increasing focus on sustainability and the mounting density of urban populations, there is a growing demand for our district cooling and heating services. We offer:

Up to 30% higher energy efficiency than conventional in-building systems by aggregating heating and cooling demands of facilities in its vicinity, coupled with optimal use of large-scale chiller system, thermal energy storage and real-time smart optimisation control through our 24/7 Operation Nerve Centre

Step into the future of comfort with Keppel EaaS.